Long time no see. I just have noticed that I didn't post anything since December, however, I have started a few posts. I am sorry guys, but recently I really don't have time to write anything and when I do, then I prefer to spend time on my other hobbies. In January this year, I have been to Poland to participate in a knife sharpening and repair workshops, as a host. These workshops had the same name as my facebook group: ''Z nożem przez kuchnię'', however, they have been organised by Michał Sadko, a knifemaker from Poland. Probably I will make a post about it because it was fun and well worth it to be there. One of the guys who has participated in that event has shown me a very damaged Deba knife. He is a sushi chef and got that knife from a restaurant which was decommissioned. He sent it to one of the sharpening services in Poland and when he got it bad he was very disappointed. His new, old knife which was already in a very bad condition has been sharpened on both sides. Now, after almost half year, I have talked to both of them and I know the story of this knife and that is the reason why I will not blame anyone for the condition of the blade and the way it was sharpened. Before, nobody was taking care of this knife and it was mostly used as a cleaver to chop off the head of the fish, and I am pretty sure that it was hardcore decapitating. This is the main reason for double-sided sharpening. When I saw it for the first time, I have decided to repair it for free, mostly because I was angry with the guy who sharpened it. Unfortunately, we have two different philosophies about knives and I explained to him many times that it is not acceptable to sharpen single bevels like he does. Anyways... I don't care now. All I wanted to do is to find some time to repair this knife.

When I was working with knives before, I could do such things quite quickly, but now it took me almost half a year and the blade was mostly hanging on my magnetic strip in my kitchen. The owner of the knife applied to a Sushi Championship in Poland and he asked me if that knife could be ready for that event. I tried my best and managed to repair that knife and even did a little extra. Let me explain what I did.

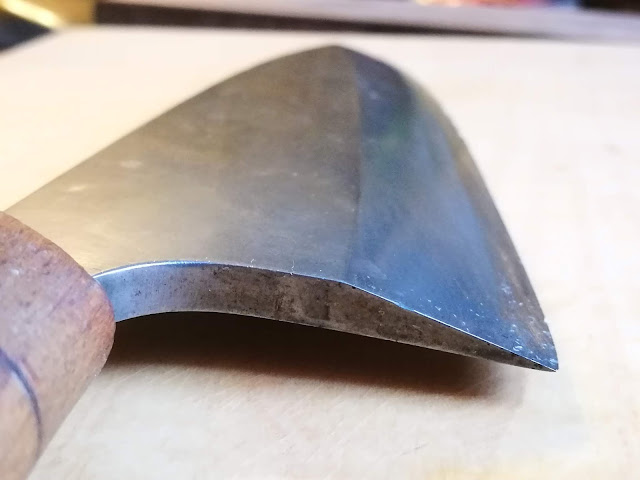

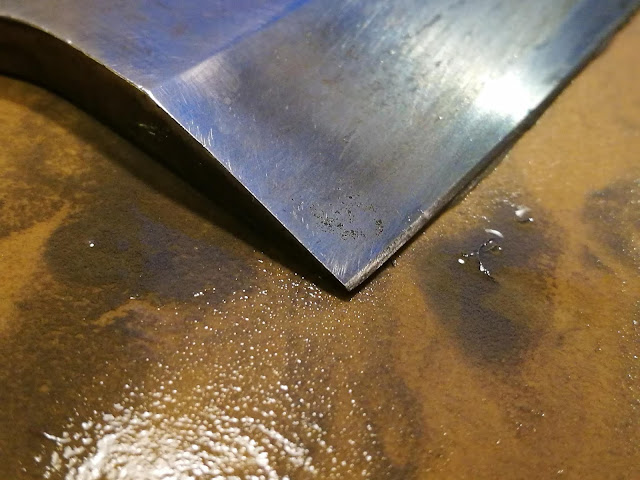

Here is the knife exactly as I got it:

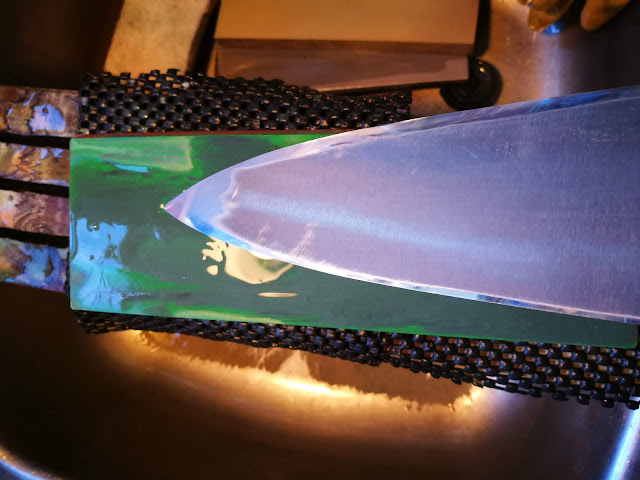

The picture below represents how bad the situation is. You can clearly see the huge bevel on the back side.

I am sure, that the very first thing you have noticed is the back of the knife - ''ura''. This knife has a bevel on both sides. Let me make it clear why this way of sharpening is a big mistake and why nobody should do that:

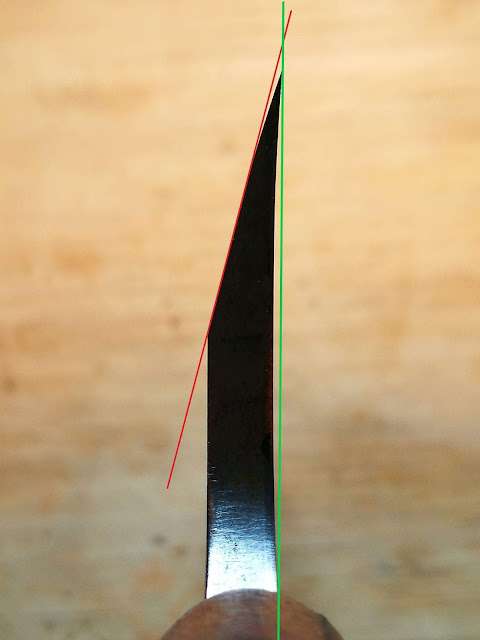

- This is a single bevel knife. It was designed in a very specific way and this construction is needed to perform special techniques which were thought for this knife.

- Single bevel knives are easy to maintain if they are sharpened properly and on a regular basis.

- It is crucial to keep back of the knife flat. Otherwise, you will change the centre point of the knife (which is already off-centred) and every time when you sharpen it again you will change that centre point. Maybe you won't notice that on the deba knife, but do that on yanagiba or usuba and these knives will become almost unusable.

- Every time you sharpen back of the knife you will make the bevel bigger and the problem will rise to the point where there won't be a way back. Also sharpening will become harder and harder.

That was the plan to repair that knife:

- Clean the blade and check the condition of the whole knife

- Repair the back of the knife

- Repair the bevel on the front

- Clean, re-sand and polish the flat area on the front

- Sharpen and polish the bevel

Everything above was the basic plan, but I did a little extra. Let's start then.

I don't like to waste my time and I knew that I have a lot of material to remove in order to make the back flat, so I have used some 80 grit corundum powder on a diamond plate.

As always, I have covered the blade with a marker pen to see what is happening. After some time of flattening the back, I could see how far I have to go. That back bevel was huge.

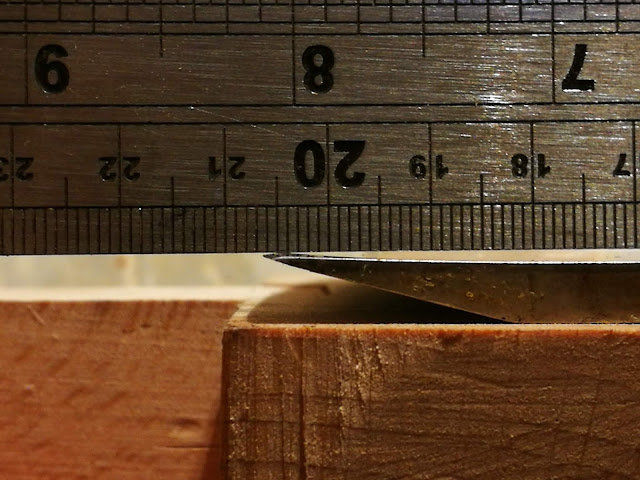

Take a look at the picture below. I had to remove a lot of material on the ''ura'' side and even then, the bevel was still visible.

Next was the time to work on the front of the knife. I knew that I will have to repair the edge, make it even and then to recreate the whole bevel, so I raised the angle to 60 - 70 degrees to remove steel quickly.

The burr that was going out from the edge was enormous.

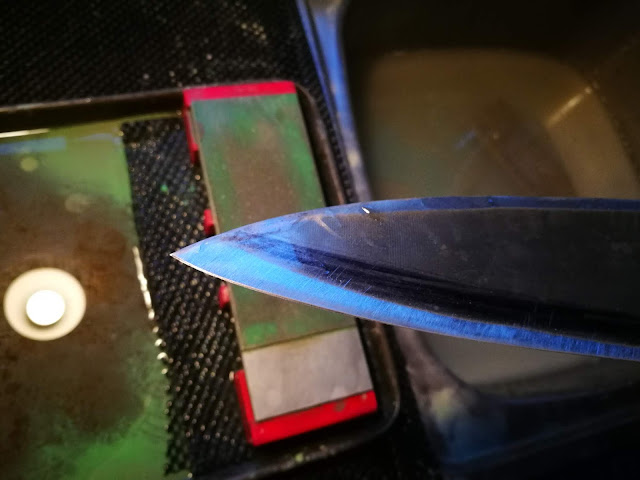

I have polished the back to 8k on the Shapton Pro and sharpened it, so from that point the knife was usable and I was able to focus on making it nice.

Now you can compare these two pictures. It is still not very good on the back, but it is possible to sharpen that deba in the traditional way. My next step was restoring the bevel on the front and making hamaguriba as well as repair the ura.

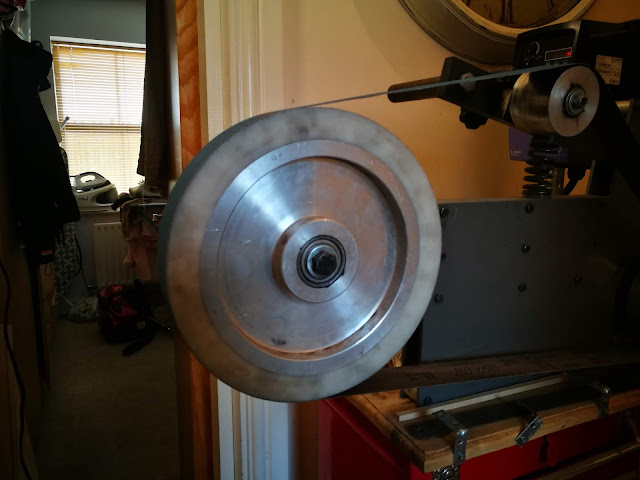

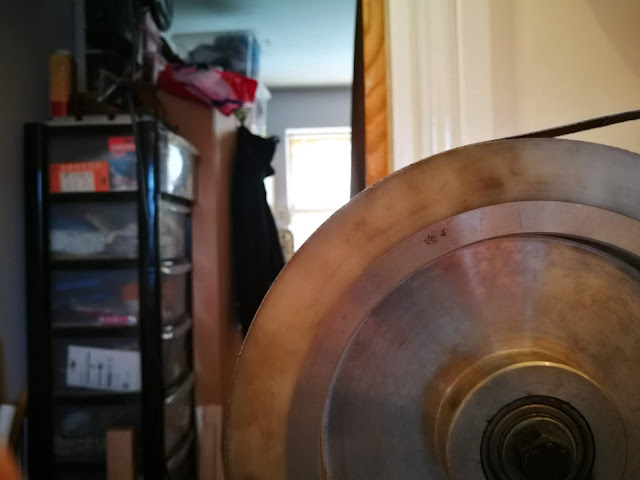

Let's fix the ura. This is a tricky part, especially if you don't have a 40 or 70'' Japanese grinding wheel or radius platen. I have only 6'' and 10'' contact wheel and this is definitely not enough. I am not saying that it is not possible, but without experience, things may go wrong.

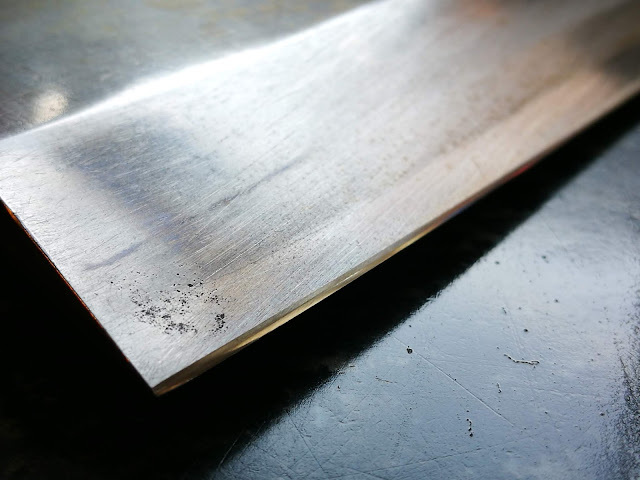

The picture below shows ura after the first session of grinding. Parts which has contact with sharpening stones are very uneven, but I will try to make it as even as I can.

Session #2: It looks a little better. I think that I have touched the flat part near the spine next to the tip of the blade.

Here it is after the last session. From that point, I will do it manually.

I know that I said that I will do it manually, but I was really annoyed by the fact that the surfaces that have contact with the stone were too wide, so I decided to use the Dremel tool to make them narrower. Unfortunately, I don't have any pictures from that part of the repair.

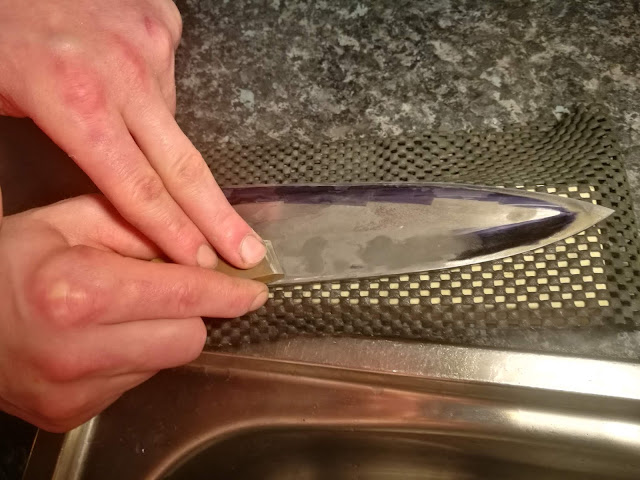

Dremel has left very deep and very ugly dips. I had to make everything even, remove the scratches and obviously hollows left by the Dremel. In order to do that I have used ura fixers. I don't know their grit. All I remember is that it took ages to finish...

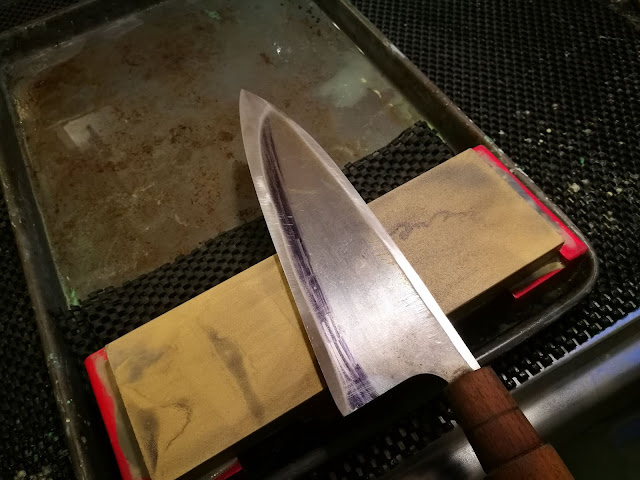

As the ura was almost fixed, I could take care of the front of the knife. I really don't understand what happened to this knife and what the previous sharpener had in his mind, but I could see the consequences straight away. To make it easier for you, I drew the line exactly on the scratch pattern edge. I don't know how previous guys sharpened it, but I definitely couldn't repeat it.

Here it is after the first ''hardcore'' session on the stones. I tried to straighten the shinogi line. You can clearly see how uneven was the edge.

Also, compare these pictures:

''Hamaguriba'':

I was quite annoyed by the scratch pattern on the flat part above the shinogi, so I decided to clean it and polish it. It was quite easy because there is no kanji on this knife. I know that this part of the blade is made on the circular grinding wheel and it is concaved, so I used a diamond plate to make it flat and to make my work easier. Also, I removed the handle to make everything more accessible.

I have started with 120 grit diamond plate. As you can notice, there is a huge low spot near the spine.

The picture below shows that part of a knife after 120 grit diamond plate. After that it was followed by 400 diamond, Naniwa Chosera 1k, Maruoyama Shiro Suita and then, just before finishing everything, I have used Shiki Uchigumori powder.

I have cleaned and polished the back with some finger stones.

That's all. I am very happy that after such a long time I have managed to repair that knife. It took me a long time, but this is due to my new job, hobbies and lack of time. I have a few postponed posts and I promise that I will try to write more on my blog and post the old stuff.

When I took that knife from the current owner, I didn't promise him anything. I just said that I will repair it. However, after putting all that effort into that knife I thought, that it will be nice if I will do something extra. That is why I made a handle, matching saya and box. Handle and saya are made from oak found in the bin at work and ferrule is made out of american walnut. The box is made from ash which was found in the bin as well. Unfortunately, it was already quite late and I had to pack this knife and send it, so I wasn't able to take better pictures. I hope that you enjoy it.